Before cutting steel, it’s critical to ensure that your part and mold designs are fully optimized for manufacturability, performance, and cost. At All In One Plastics, our Design for Manufacturability (DFM) and mold design review services help eliminate issues before they become expensive problems.

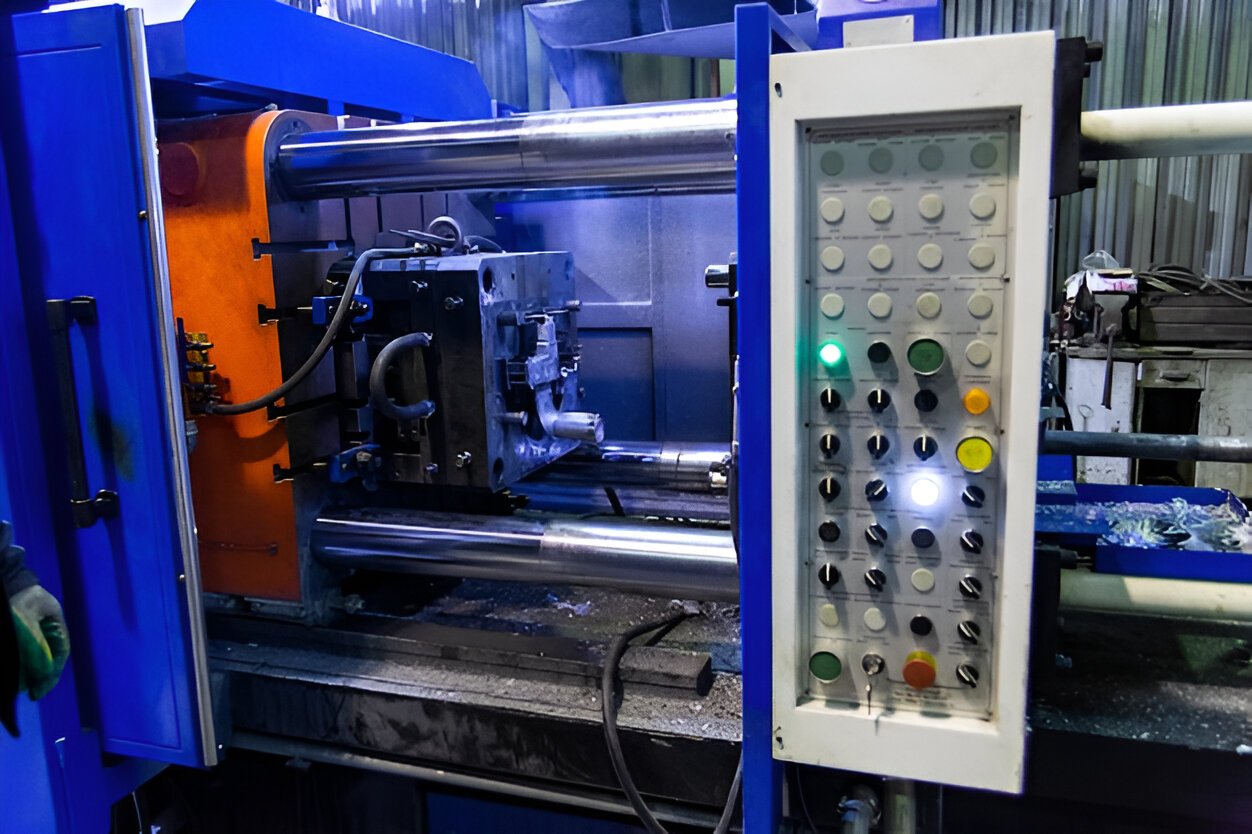

We carefully review your part geometry, wall thickness, draft angles, gating, venting, and ejection strategies to ensure the part can be molded consistently and efficiently. Our engineers use decades of real-world experience—along with tools like mold flow analysis—to validate and optimize the design for the specific resin, application, and production volume.

We also perform detailed reviews of tooling layouts and mold design files—whether provided by your supplier or developed through us—to confirm proper function, longevity, and alignment with your project goals. Every design review is done with cost-efficiency and production scalability in mind.

By identifying and addressing issues early in the process, we help you:

- Avoid costly tooling changes

- Improve cycle times and part quality

- Ensure smooth production ramp-up

- Extend the life of your mold investment

With All In One Plastics, you gain confidence knowing your mold is engineered right—before it’s ever built.